The Basics of Web Handling Processes

September 6, 2021

What are the Basics of Web Handling Processes?

Many finished goods are manufactured from one or more wide continuous flexible rolls of prefabricated material known as a web. Web materials can include thin plastics, paper, metal sheets, plastic films, foil, textiles, or other materials. Converting refers to processes that permanently alter web materials into an intermediate product for subsequent processing or a final product delivered in many forms. Common converting processes include coating, plating, laminating, extrusion, calendering, stamping, embossing, cutting, and slitting.

Web Handling Sections

The example shown in Figure 1 consists of three major sections. The Unwind section provides the supply of material with its drive and braking control system. The Process section is equipped with its own drive system to act upon the web material with its converting process. The Rewind section collects the processed product onto a roll (or alternate form) at the end of the line.

Between each section is a tension monitoring system. An actual line may perform two or more web processes with multiple unwind and rewind terminations and tension management. Each section operates individually but may be configured to coordinate with adjacent sections.

Figure 1: Example Web Manufacturing Line

Web material aligns itself perpendicular to the idler or driven rolls as long as the web remains in traction. Tension must be applied to keep the web in traction. Control of tension is crucial for keeping the web undamaged by wrinkles or web breaks. It’s also important for preventing poor process results such as interweaving, inconsistent coating thickness, length variations, and roll defects.

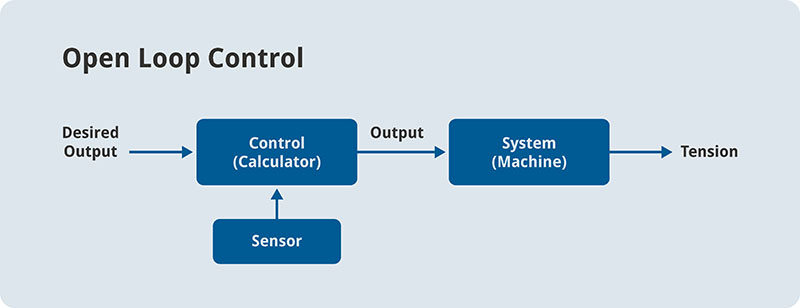

Open-Loop Tension Control

Figure 2: Open Loop Control Example

Open-loop controls manage tension indirectly by using calculations based on sensor data as the web moves from start to finish. The controller logic accounts for unwind or rewind roll diameters, expected torque, and speed to maintain constant web velocity at the desired tension. With tension accuracy within 10 to 20 percent, an open-loop control can be the most economical solution if the line can tolerate variation.

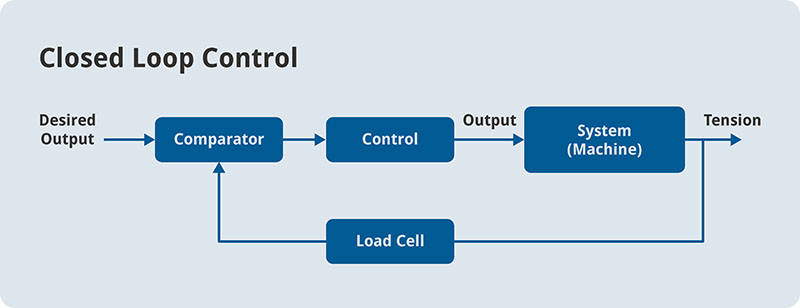

Closed-Loop Tension Control

Figure 3: Closed Loop Control Example

Closed-loop systems use measurement points to provide direct feedback for tension corrections. Generally, a closed-loop control design must be used for all sections that require web materials to start, accelerate, decelerate, stop, and compensate for process variations.

Common Measurement Techniques

Load Cell / Tension Sensor

Load cells provide compressive force conversion to an electrical signal for feedback to controllers. Tension sensors perform similarly except for loads in tension. Either or both can be used to register pressure against a roller, the weight of unwind/rewind rolls, calender roll pressure, or other parameters.

Dancer Position Data

The dancer roller remains in traction with the web. However, it moves in response to changes in web velocity while keeping a tension against the material. Position signaling from the dancer allows the controller to affect changes to drive operations as necessary.

Follower Arm and Proximity Sensors

A follower arm tracks against unwind or rewind rollers to indicate radius or diameter to the controller. Proximity sensors function similarly but with no contact with the material.

Other Data Sources

If temperature, torque, pressure, rotation, speed, or other conditions can affect operational adjustments, data point sensors will be added to enhance closed-loop controls.

Summary

Web fed manufacturing systems use a broad array of methods to maintain sufficient tension between unwind to process and process to rewind stages. More precise web tension management is achieved using closed-loop controls. Actual tension maximums must be determined according to the materials to be processed, web dimensions, and process requirements.