Company News | Quad Plus Company Blog

A collection of news and articles

Categories

Recent Posts

Understanding Electrical Substations

Electrical substations play a critical role in ensuring efficient and reliable power distribution. These facilities act as pivotal points within electrical networks, facilitating the transmission, distribution, and management of electrical energy. This guide explores the purpose of substations and their importance to help you understand critical role in electrical systems, [...]

How to Repair Industrial Circuit Breakers

What are industrial circuit breakers? Industrial circuit breakers are specialized electrical components designed to protect electrical circuits and equipment within industrial environments. Often classified by voltage class and type, they serve a crucial role in safeguarding against overloads, short circuits, and other electrical faults that could lead to damage, fires, [...]

E-House Technology

The e-house industry is growing at a 6.83% growth rate. The fastest-growing market is Asia Pacific; North America, however, is the largest market. The Basics of an E-House An E-house is a custom pre-fabricated piece of infrastructure built off-site. These e-houses, specifically those with built-in controls, are delivered pre-tested for [...]

How to Avoid Extra Charges from Your Power Company and Fix Your Power Factor Problems

While most people believe that lower power should mean lower energy bills and fewer penalty fees, this is not the reality. The truth is that a lower power factor will cost you more over the long haul. The majority of utility companies charge a "demand fee" if the "power factor" [...]

How often should switchgear be tested?

First, let's cut to the chase. Generally speaking, switchgear testing should be completed semi-annually with a visual inspection and infrared completed annually. There may be some factors that would warrant more frequent testing, such as equipment issues or deterioration, manufacturer defects, or high reliability requirements. Your Schedule or the Machine's? [...]

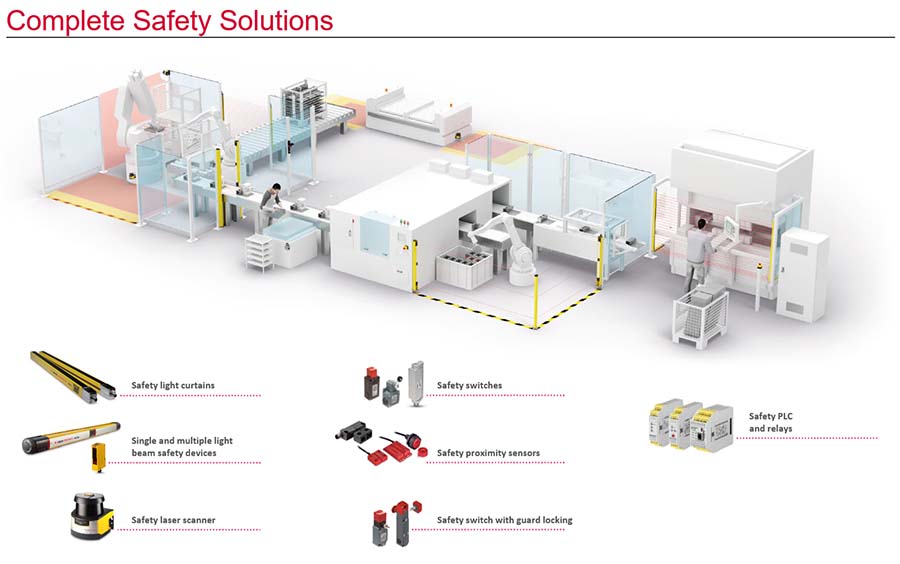

What is the Difference Between Standard and Safety PLCs?

Waiting for an accident to happen is no way to operate. Manufacturers around the world invest a considerable amount of resources into making the workplace safer for their crews while also protecting their equipment and products. Safety programmable logic controllers (PLCs) are a step in the right direction in terms [...]

When is Lockout Tagout Required?

The purpose of lockout/tagout procedures is to control hazardous energy sources so that employees are not in danger when servicing and maintaining machines and equipment. Energy sources regulated by OSHA include electrical, chemical, pneumatic, mechanical, hydraulic, and more. OSHA standards also have requirements for when lockout/tagout is necessary for people [...]

Improve Your Building Infrastructure or Rebuild?

From updating existing structures to comply with current building codes to improving the efficiency, sustainability, and profitability of operations, building and factory managers face a tall order when maintaining older structures. In most cases, regular repairs and improvement can postpone major building projects, but eventually, every construction will reach the [...]

Increase Your Capacity With Expansion of Your Facilities

Whether it’s adding new lines of products or expanding your capabilities to deliver higher quantities of products, a focus on growth is ubiquitous across all industries. What happens, then, when the infrastructure of the building reaches capacity and prevents additional growth? The options include moving to a larger facility, building [...]

What is a Machine Risk Assessment?

Industrial and manufacturing facilities can be dangerous places for workers and the public. To ensure the safety of work crews and the machinery they operate, systematically collecting information on necessary improvements is important. The task becomes critical when complex industrial machinery and sophisticated automation tools are used. A machine risk [...]

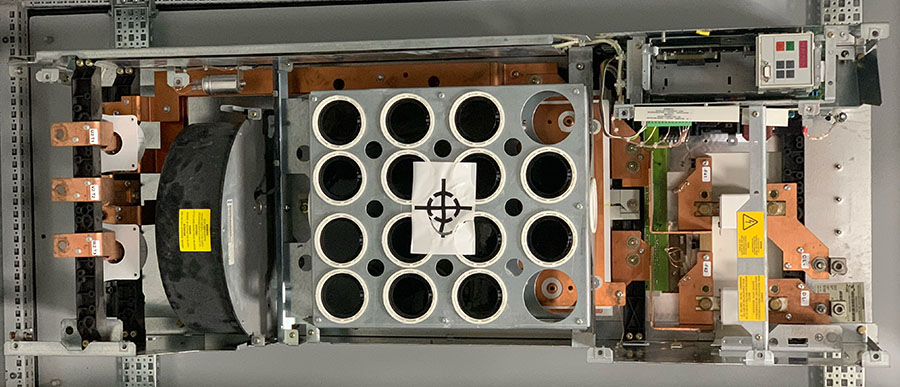

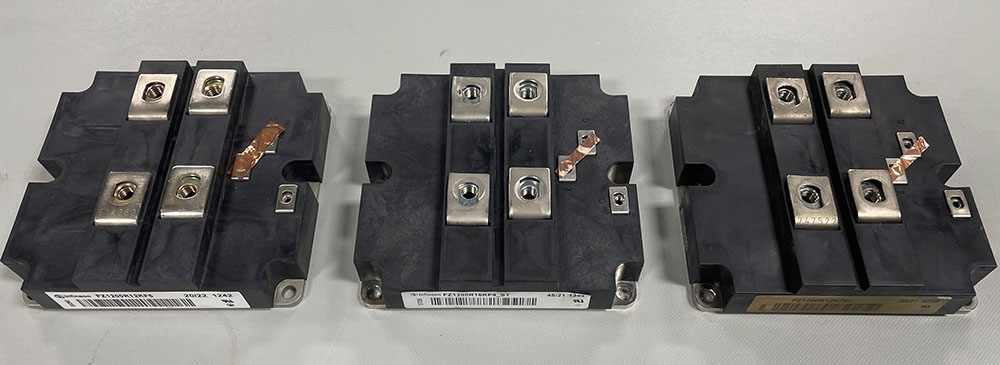

Preventive Maintenance: VFD Repair vs. Replacement

Variable frequency drives (VFDs) have helped businesses and manufacturers in nearly every sector enjoy significant energy savings for decades. Their increased use during the last decade has been driven by both the demand for energy efficiency and regulations requiring such improvements. The result is that VFDs are considered the standard [...]

Counterfeit Electronic Components an Overview

Almost all finished goods are produced by, contain, or manufactured with systems using electronic parts that manage operations. The semiconductor market alone continues to expand past the $425.96 billion mark measured in 2020. With high demand and constrained supply due to current economic factors, genuine product prices have increased along [...]

Why is machine safeguarding important?

The worst-case scenario for any manufacturer is an injury in the workplace. Protecting workers from machine-related injuries is always a priority. According to OSHA, workers who operate and maintain machinery experience as many as 18,000 injuries every year, including everything from bruising and scrapes to amputations, lacerations, blindness, and even [...]

What are the types of machine guards?

Protecting against the hazards created by mechanical motion is not only a priority for manufacturers; it’s also required by law. OSHA regulations state that at least one method of machine guarding must be supplied to protect workers in the machine area from hazards at the point of operation. Employers must [...]

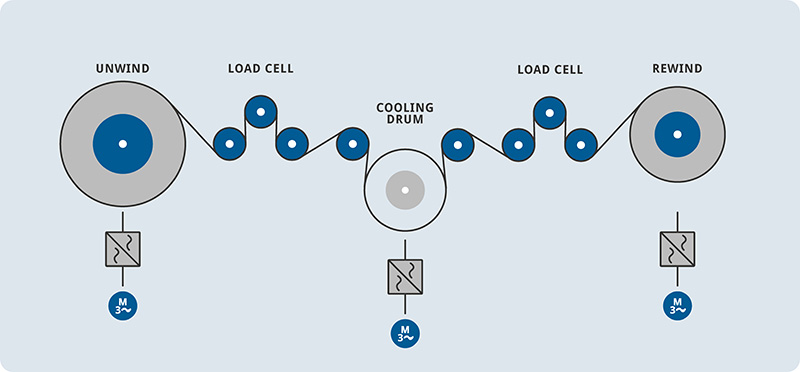

Web Tension Control for Web Handling

A Three Section Coordinated System Web Tension Control For Web Handling Basics In coordinated drive systems on production machines, coordination is the operation of all individual sections and the overall control so that the process machine functions as a single entity. This means that all drives and devices (sections) must [...]