Preventive Maintenance: VFD Repair vs. Replacement

February 1, 2022

Variable frequency drives (VFDs) have helped businesses and manufacturers in nearly every sector enjoy significant energy savings for decades. Their increased use during the last decade has been driven by both the demand for energy efficiency and regulations requiring such improvements. The result is that VFDs are considered the standard for modern motor control.

However, these types of drives are more complicated and feature more numerous parts when compared to older technology. When something goes wrong, many technicians may immediately move to replace a failed VFD, but VFD repair may be the better option.

Determining the Root Cause of Failure

It is not uncommon for VFDs to simply be deemed inoperable, and a replacement drive is requested. However, a unit that has been properly repaired and well-maintained could easily deliver another ten years of useful life. Contacting qualified variable frequency drive repair services can help you make the following determinations.

There are a number of factors that could contribute to a failure, and not all are catastrophic. Environmental quality, including humidity levels, temperature, dust and particulates, and exposure to moisture or corroding agents are all common problems that could contribute to a drive failure that is repairable. External issues such as problems with the motor and fluctuations in input voltage could strain internal components and cause failure.

In cases where internal components become damaged, repairing the VFD becomes mainly an effort of sourcing parts. The next step is determining whether the sum of the parts compared to the cost of replacement makes sense. An experienced repair team can help determine if a drive is a non-economical repair (NER) or determine whether it makes financial sense to repair rather than replace the drive.

Factors to Consider When Repairing VFDs

There are two main factors to consider when deciding whether to repair or replace a VFD. The first is the age and lifecycle stage of the drive. As a drive moves through the phases from Active to Obsolete, obtaining parts will become increasingly difficult.

Depending on the drive type and application, finding an experienced technician to complete the repair can also be challenging. In many cases, a qualified repair tech will be able to advise whether it’s possible to source replacement parts for a drive.

The other factor is how vital the specific drive is to your overall operation. If a critical drive fails, the associated downtime starts to rack up cost by the minute. If repairing the drive is feasible and makes financial sense, can it be repaired quickly enough to alleviate the cost of the potentially longer downtime? Does the shop you’ve contracted for repair have solutions to keep your operations running should your repair require an extended amount of time?

Lastly, the complexity of the system is a consideration. Some drive systems are highly integrated with special communications or technology and off-the-shelf replacements may not be available. An upgrade would not only require updating the drive, but also the overall control system, including PLCs, HMIs, etc.

Preventive Maintenance for the Win

Of course, the best time to perform preventive maintenance on a VFD is before it has failed and during a planned time for maintenance. Most manufacturers and industrial operations use regular maintenance schedules to inspect individual items and perform routine maintenance. The problem is that these lists typically include mechanical components such as pumps, bearings, belts, and motors, but not enough scrutiny on the electrical side.

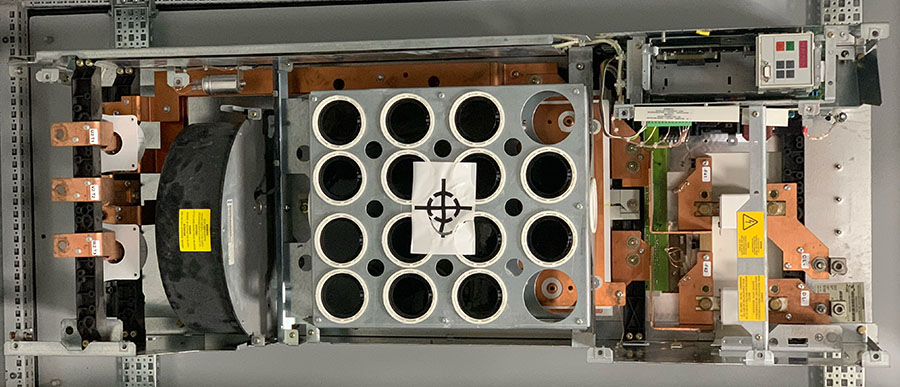

Components such as drives are not often on the list of regular inspections and only receive attention when something has gone wrong. Instead, regularly analyzing error codes along with the inspection of capacitors and PCBs is necessary. Testing insulation resistance, checking fans and ventilation, and using thermal tools to spot loose connections and overheating components is critical. Lastly, clearing the drive’s heat sink vents from obstructions such as dust, dirt, and grime can help improve the drive’s operational temperature and prolong normal operation.

Planning for the future is the best way to help ensure that all systems are up and running when you need them the most. Having spares for critical components will bridge the gap between a failure and a planned replacement. All mission critical drive systems should have contingency plans for failures along with long-term plans for when spares are no longer available.

Refurbish and Retrofit to Extend Useful Life

If problems are detected during regular maintenance and inspection of your VFDs, but the drives are still operational, you also have the option to refurbish the drive. This process involves changing all electrolytic capacitors on the circuit boards and the main capacitors on the DC link. In many cases, swapping the circuit cards to the newest versions is less costly than changing the capacitors at the component level. In some cases, especially on older drives, this may not be possible as replacement boards may be unavailable. Your repair team should be happy to help you evaluate their boards and make repairs when replacements are not available.

Regular inspection and refurbishment of VFDs is the best way to ensure that maintenance occurs on your schedule rather than causing downtime due to a drive failure. However, if the drive is already scheduled for replacement in the near future, the cost of refurbishment may not be a good investment. When it’s finally time to replace or upgrade your VFDs, a retrofit option may be available. This will allow a new drive to be installed using the existing wiring and enclosure.

Don’t Start with Replacement

While immediately ordering a replacement for a failed VFD is the most straightforward option, it’s not always the best. Qualified repair technicians can often repair a damaged drive and can usually source replacement parts, even for obsolete drives.

The best option will always be to take action before problems arise. In these cases, making minor repairs or refurbishing the VFD during a period of planned downtime will always save on the cost and hassle of an unplanned shutdown. When you’re out of repair options, it always pays to see if a retrofit is possible to reduce waste and keep expenses in check.