Electrical Power Systems Testing

Our NETA-accredited technicians are readily available to help you identify and resolve any manufacturing defects, buildout deviations, and errors. By doing so, you’ll avoid startup delays and unexpected downtime, as well as steer clear of expensive electrical issues. Ultimately, this will save you money in the long run.

Whether you’re acceptance testing new equipment or maintenance testing your current setup, all of our electrical testing is done in accordance with the NETA/ANSI Certified Standards. Our professional engineers are specialists in proactive and reactive power studies.

Electrical Power Services & Results

During acceptance testing, your electrical equipment will be thoroughly examined following installation and wiring to make sure all equipment, switches, and connections are fit for service.

The maintenance testing and inspecting process includes thoroughly inspecting existing equipment and making recommendations so you can enjoy years from your machinery without worrying about unexpected downtime or spending millions of dollars on repairs and new equipment.

When you have challenging projects, you need a proven partner with the knowledge and expertise to find a solution that works for you.

Electrical Power System Testing

We pride ourselves on zero issue first-time power-up and electrical equipment restoration up to 345kV. If your equipment has problems, you’ll receive recommendations for corrective actions. You can expect a quick and accurate turnaround on test reports to ensure no project gets delayed.

Acceptance Testing

Ensure proper installation for the safe operation of your new equipment.

Your equipment will be thoroughly examined following installation and wiring into your electrical power system to ensure all components, switches, and connections pass the grade for safe installation and operation.

- Transformer Testing

- Circuit Breaker Testing

- Cable Testing

- Switchgear Testing

- Protective Relay Testing

- Battery Testing

- Generator/Motor Testing

- Meter Testing

Commissioning

Your new electrical power system startup is a complex process and unique occurrence.

Commissioning by NETA-accredited professionals through whole-system functional checks will ensure proper operation, identify installation problems, and assure total power system performance.

Enjoy a wide variety of commissioning support including, but not limited to:

- Infrared Scans/Surveys

- Utility Phasing

- Coordination Study Verification

- Power Quality Analysis

- Startup Support

Maintenance Testing

Regular maintenance saves time, money, delays, and headaches.

Establishing trends of baseline data is important in maintaining a reliable electrical system. Regular maintenance allows you to track the expected lifetime of equipment and make timely replacements or repairs to issues before a potentially costly incident occurs. According to NETA MTS-2019 Appendix B, electrical and mechanical maintenance testing is recommended to be performed at the regular intervals listed below for equipment with an average requirement.

- Transformer Testing

- Cable Testing

- Circuit Breaker Testing

- Power Quality Analysis/Load Monitoring

- Incoming Switchgear Testing

- Battery Testing

- Generator/Motor Testing

- IR Scans

- Exercise/Cleaning

- Protective Relay Testing

- Visual & Mechanical and Replacement Inspections/Checking

Read more about the importance of electrical maintenance testing with our guide.

Additional Services

We are your experienced industrial partner, bringing success to all your electrical power testing projects. Our knowledgeable team provide support across additional services, from cable assembly & testing, proactive power studies & analysis, reactive power studies & analysis and synchronous motors retrofit to electrical infrastructure design and automation.

Cable Assembly & Testing

Electrical cables provide critical links throughout your systems.

Cable testing is vital for ensuring that your cables operate safely and reliably. New cables must demonstrate that they are safe to energize and hold up during operation. Older cables must be examined to ensure they continue to perform safely and provide insight into the cable’s remaining useful life.

That’s why you need engineers like ours, who have the training and experience to not only perform the correct tests, but also to interpret the data collected and provide actionable recommendations.

- Locate, isolate, and trace a cable fault on shielded cables using multiple testing types during both acceptance and maintenance testing.

- Very low frequency testing places less stress on your cables than AC and DC high-potential testing while also providing accurate results to check installation quality.

- Predictive and preventive maintenance programs involve partial discharge testing.

- Tan Delta testing can identify degrading cables when used regularly.

- DC high potential testing should generally be avoided for older cables but is still available when necessary.

Synchronous Motors Retrofits

A regular maintenance program allows synchronous motors to continue running for many years.

You need to get the longest possible working life from your synchronous motors and that means regular replacement of controls, relays, and DC contactors. For machines that are obsolete and no longer supported by the manufacturer, this becomes increasingly difficult every year.

You need a partner with an extensive network to source parts for obsolete machines and a crew with the right experience to perform repairs and retrofit synchronous motors with new field control circuits when replacement parts are no longer available.

To stay ahead of your competitors, it pays to implement innovations that go beyond simply replacing parts. We design and build each electrical power system for motors, rather than adapting systems from generators to motors. In particular, we build a power factor regulator into all of our systems to ensure your motors are running at peak efficiency.

We have installed more than 65 synchronous motors and can supply references from major companies to demonstrate our work.

Proactive Power Studies and Analysis

Optimize your power system’s performance and improve safety.

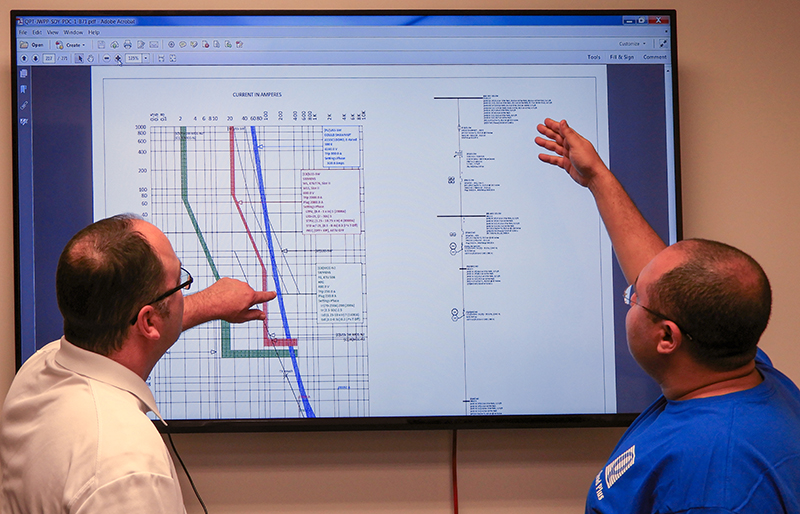

Standard and specialized power system studies, along with pre- and post-installation power quality audits, will precisely target and correct your power issues.

Professional engineers who specialize in low and medium-voltage power systems conduct the studies in accordance with applicable industry standards from the Institute of Electrical and Electronics Engineers (IEEE), the American National Standards Institute (ANSI), the National Fire Protection Association (NFPA), and the National Electrical Code (NEC).

- Arc Flash Hazard Analysis

- Coordination Studies

- Ground Grid Analysis

- Harmonics and Flicker Analysis

- Load Flow Studies

- Power Factor Correction Studies

- Short Circuit Studies

- Transient Motor Starting Analysis

Reactive Power Studies and Analysis

Let’s get to the source of your problems and solve them.

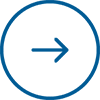

If you have an existing problem with the power company, our system integrators will find the source and recommend solutions. You can start with a power study that will model the control system on the local power grid and show its effect on the electrical system. For most sites, flicker will be the most serious issue, but we can also model other power quality issues such as harmonics and power factor.

Our work has spanned the globe and our engineers come from every industry. Let us use our vast and varied experience to eliminate your electrical power issues and improve your profitability.

Power Company Experts

Working with the power company can seem like a job in itself. From scheduling power studies and presenting results to the power company, attending meetings, completing paperwork, and receiving approval for connection design and equipment, it helps to have an ally on your side. We can provide you with advice for lowering your power bill, review local power company connection requirements, and coordinate connections between the wire on the poles and your equipment.

When it’s time for negotiations with the power company to get approval for your site, you’ll need an accurate, complete data set to ensure an outcome in your favor. Our power study service furnishes everything you need: a power single-line diagram of the facility, flicker analysis, and power quality standards compared to our findings and recommendations for meeting IEEE and local quality standards in the most cost-effective manner.

Related Videos

Electrical Infrastructure Design & Automation

Design, install, and maintain your complete electrical infrastructure and power systems.

Substation and power distribution system design and automation, including:

- industry electrical requirements

- compliance with government regulations

- load analysis

- system layout and calculations

- sizing and specifications for cables

- cable trays system

- conduit system design and installation

- transformers

- protective devices

- panels, switchgear

- capacitor bans and other required equipment

Cable layouts will be clear of site traffic while guaranteeing you the most cost-effective layout.

We specialize in keeping our clients up and running.

Your Experienced Partner When Projects Are Difficult

We have the knowledge and expertise to find a solution that works for you. Quad Plus provides much more than power services; we offer all the services in the system integration lifecycle to our local and global customers. Quad Plus is a trusted provider of multi-discipline professional engineering, system integration, commissioning, repair/service, and industrial safety.

Your Industries are Our Industries

Our team of system integrators and process engineers have years of experience in every industry. Many of our engineers have worked in the specific industry before joining Quad Plus, so they have extensive knowledge of your industrial control systems and production lines.